Engineering for SI / PI

Signal integrity or SI is a set of measures (ringing, crosstalk, coupling, dielectric loss, reflections, etc.) of the quality of an electrical signal. In digital electronics, a stream of binary values is represented by a voltage (or current) waveform. However, digital signals are fundamentally analog in nature, and all signals are subject to effects such as noise, distortion, and loss. Over short distances and at low bit rates, a simple conductor can transmit this with sufficient fidelity. At high bit rates and over longer distances, as seen in the typical interface board, or through various mediums or materials, these varying effects can degrade the electrical signal to the point where less-than-ideal conditions (errors) occur, and the system or device fails. Signal integrity engineering is the task of analyzing and mitigating these effects.

SI analysis has become an essential part of today’s electronics and especially in today’s A.T.E. interface board designs. Our Signal Integrity engineers look to incorporate real – world, practical solutions in assisting you with design and engineering of your interface board test requirements. We help turn complex signal integrity concerns into designs that function on your test floor.

Because we are part of a complete, turn-key solution for ATE interface boards, we understand the limits of the interconnect technology (laminate, conductors and via’s, connectors and sockets) and use that understanding to guide our principles of design.

We utilize design methodologies well suited to our fabrication capabilities, identifying and eliminating problems before they get into your design. We are concerned, too, with cost and performance trade-offs and we offer those comparisons, right up front. You get to decide and you know what you are getting. We offer services for modeling and simulation and complement that work with measurement and validation of those models, at your desired frequency and your required fidelity specifications.

Our SI team has over one hundred years of combined experience in SI and Power Integrity or PI modeling, instruction, measurement and DEBUG. Our design and programming expertise includes: Teradyne Catalyst through Integra FLEX; Advantest 3340 through T2000; Verigy 82000 through 93000.

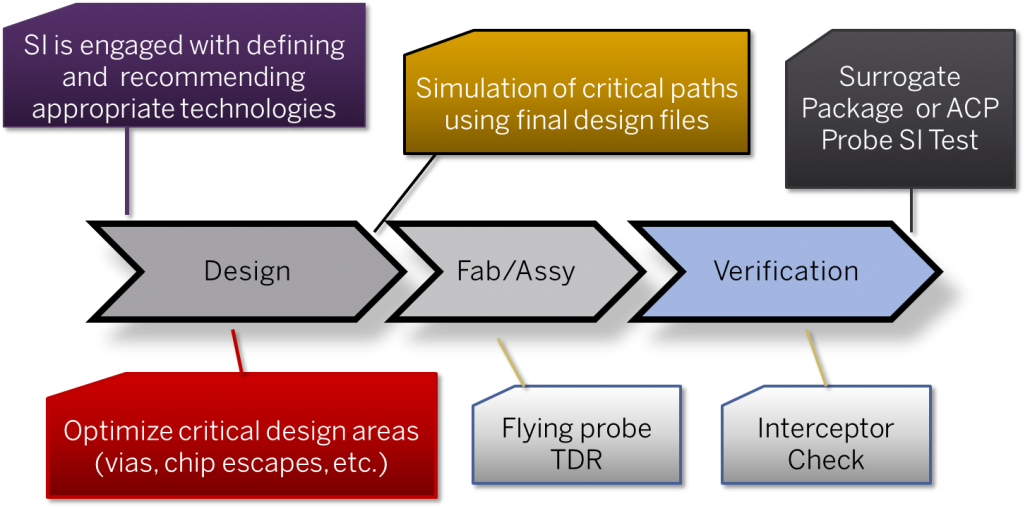

Our SI/PI team will sit down with you to determine your critical test requirements and recommend appropriate solutions from the R&D Altanova suite of test board fabrication technologies. This includes simulation of those critical paths from tester channel resource right through to the socket. After simulation, they will work with our design and fabrication teams to optimize critical areas to insure the best possible signal response. Once the boards are component assembled, there is a verification check on our Interceptor tester and finally a validation check can be performed to the DUT pad or through the socket with our semi-automated VNA test system.

Some of our modeling and measurement resources include:

- 3D Modeling

- ANSYS HFSS

- SolidWorks (for front-end)

- 2½D Modeling

- Agilent EEsof tool suite (ADS)

- HyperLynx® LineSim GHz™

- Analog

- HSPICE

- Mathcad

- Thermal Modeling

- HyperLynx® Thermal

- SolidWorks Thermal

- Measurement Labs (up to 50 GHz)

- VNA & TDR