Board Manufacturing

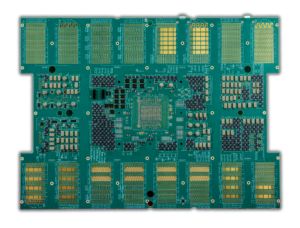

At R&D Altanova Advantest Group, we excel in manufacturing high aspect ratio boards, with proven capabilities of achieving aspect ratios up to 35:1 and beyond. Our facilities are equipped with high-speed drilling machines, X-ray drilling, and laser drilling and routing, ensuring precision and quality in our products. As a result, the expertise of our highly skilled engineering team ensures optimal manufacturing yields and competitive pricing.

Our integrated SI/PI engineering and design teams offer a unique advantage as they possess in-depth knowledge of our fabrication facility’s capabilities. This enables us to create tailored solutions for our customers’ test needs, addressing issues such as stack-ups, material choices, and drilling capabilities.

We continuously improve signal performance by adjusting the anti-pad in plane layers and strategically placing ground vias. For higher-speed applications, we utilize embedded coaxial vias for a significantly better signal response.

To enhance power delivery performance, we offer our EC Technology™, embedding passive components such as capacitors and resistors directly in the PWB at critical locations. This approach improves response time and allows for termination at the pin location, saving valuable surface space.

Hybrid Lamination Technology is available across different materials to match your performance and cost requirements. Performance sensitive traces are routed on selected layers, most other traces as control and power are implemented with standard technology.

For details, please contact: [email protected]